Benchmark Abrasives Tungsten Carbide Tipped (TCT) Saw Blades for Cutting Ferrous Metals

When it comes to metalworking and welding, precision and durability are non-negotiable. One essential tool in this process is the tungsten carbide tipped saw blade. This guide will delve into the benefits, uses, and best practices for using these impressive cutting tools.

What Are Tungsten Carbide Tipped Saw Blades?

Tungsten carbide tipped (TCT) saw blades are renowned for their robustness and longevity. Tungsten carbide, a compound consisting of tungsten and carbon, is nearly as hard as diamond and provides exceptional cutting power and resistance to wear. These blades are specifically designed to slice through metals cleanly and efficiently, making them indispensable in metalworking and welding. Their cool, burr-free cuts provide unmatched finished surfaces.

Benefits of Using Tungsten Carbide Tipped Saw Blades

- SUPERIOR DURABILITY – Tungsten carbide is significantly harder than steel, meaning these blades last significantly longer and require less frequent replacements.

- ENHANCED CUTTING EFFICIENCY – The hard, sharp edges of tungsten carbide can cut through metal with ease, resulting in cleaner cuts and fewer burrs.

- VERSATILITY – Suitable for cutting various metals, including aluminum, stainless steel, and mild steel, these blades are versatile tools for any metalworking shop.

- HEAT RESISTANCE – Tungsten carbide can withstand higher temperatures, reducing the risk of blade warping or losing its temper during intensive cutting tasks. Handle the workpiece after completing your cut without getting burnt.

- REDUCED DOWNTIME – Longer blade life and fewer interruptions mean greater productivity and cost savings over time.

What Can You Cut with These Blades?

TCT saw blades are perfect for cutting pipes, beams, and sheet metal. Whether you are fabricating components or dismantling structures, these blades ensure precise cuts that meet rigorous specifications. Here are some suggested cutting applications:

- Steel – Angle Iron, Steel plate, Channel Iron, Pipe, I-beams and more…

- Stainless steel – cut up to ¼” thick stainless plate, tubing and other stainless steels used in commercial kitchen products

- Thin steel – materials less than 1/8” like corrugated roofing, sheet metal, steel studs and conduit

Benchmark TCT blade for Metal cutting are designed to cut ferrous materials. If you are looking to cut non-ferrous materials like aluminum or wood, check out our other material specific pages.

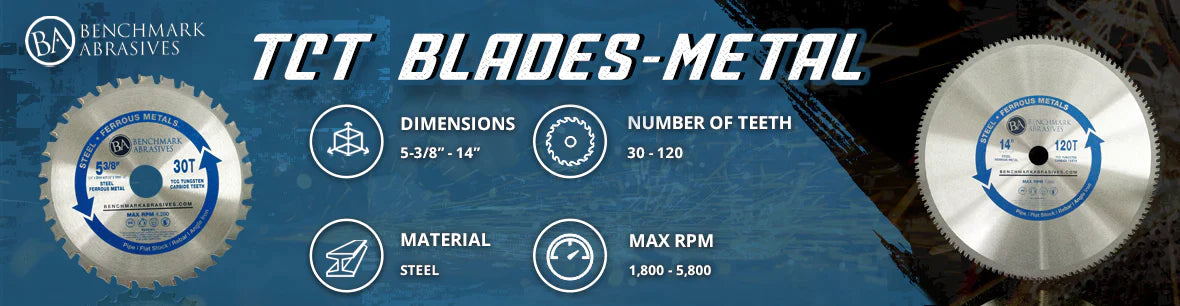

TCT Blades Available at Benchmark Abrasives

Benchmark carries three categories of TCT blades, designed to match your material and machine.

1. TCT Blades for WOOD (check out the TCT Blades for wood page for more info)

2. TCT Blades for METAL - made from tungsten carbide teeth and a solid steel circular core, designed to cut steel and other ferrous metals. This Metal cutting blade allows easy cutting through metal rods, rebar, steel sheets, steel pipes, channels, and lasts longer than abrasive discs. The TCT saw blade is specifically designed for cutting metal tubing, pipes, rails, nickel, zirconium, cobalt, and titanium-based metal. These cutting saw blades are ideal for metal cutting, delivering accuracy and resistance to bending and deflection for true cuts.

· Sizes: 5-3/8” to 14”

· Number of Teeth: 30T, 40T, 48T, 50T, 52T, 60T, 66T, 80T, 120T

· Available kerfs: 0.079” to 0.098”

Tool Compatibility: Circular Saws, Low Horse Power Saws, Miter Saws, Worm Drive Saws, MK® Diamond Saws, Evolution® Metal Cutting Saws

3. TCT Blades for ALUMINUM (check out the TCT Blades for aluminum page for more info)

Choosing the Right Tungsten Carbide Tipped Saw Blade

When selecting a TCT saw blade, consider the following factors:

- Blade Tooth Configuration: The number of teeth and their configuration will influence the cut quality and speed. Fine-toothed blades with lots of teeth are ideal for thin or delicate metals, providing smooth edges, while coarse-lower count toothed blades can quickly slice through thicker materials.

- Tooth grind: Benchmark uses Triple Chip Grind (TCG) configuration on our blades. This configuration maximizes life by sharing the chip load between teeth, allowing for a cooler cut. TCG provides superior cutting tip toughness.

- Blade Diameter: Match the blade diameter to your specific saw for optimal performance and safety.

- Metal Type: Ensure the blade's design is suited to the metal you intend to cut.

Maintenance Tips for Longevity

- Regular Cleaning. Remove debris and buildup from the blade, using a wire brush or specialized cleaner.

- Proper Storage. Store blades in a dry, cool place to avoid rust and other environmental damage.

- Routine Inspection. Check for signs of wear or damage before each use to ensure safety and efficiency. If your blade is warped it will not provide straight cuts.

- Professional Sharpening. When blades start to dull, have them sharpened by a professional to maintain cutting precision.

- Increase the useful life of your blade with our saw blade lubricant. The specially engineered tube wax will coat the cutting edge of your blades teeth, providing quick clog free cuts. Faster Cuts, Sharper Teeth, Longer Blade Life!!!

Machine Brands that are compatible with Benchmark TCT Blades for Steel

- Bosch®

- DeWalt®

- Makita®

- Milwaukee®

- Panasonic®

- Skil®

- Hitachi®

- Ryobi®

- Evolution®

- Metal Devil®

- Porter-Cable®

- Jepson®

- Other Low Horse Power Saws

Machine Selection by Blade Size

Check out this handy chart for suggested machine brands best suited for each size of blade.

|

Blade Diameter |

Max RPM |

Compatible Machine Brands |

|

5-3/8" |

4200 |

Panasonic®, DeWalt®, Bosch®, Makita®, Milwuakee®, Skil®, 5-1/2" Ryobi® |

|

6-1/2" |

4600 |

DeWalt®, Milwuakee®, corded and cordless |

|

7-1/4" |

5800 |

Corded and Corsdless Circualr Saws - ALL brands |

|

8" |

5800 |

Milwaukee® 8-1/4" Wormdrive Saws |

|

8-1/4" |

5800 |

Evolution® Fury3®, corded and cordless |

|

9" |

3200 |

Hitachi®, Jancy®, Evolution®, Metal Devil® |

|

10" |

5200 |

Evolution®, Miter Saws |

|

12" |

2000 |

Jepson®, Makita®, Ridge®, Ryobi® |

|

14" |

1800 |

DeWalt®, Jepson®, Hitachi®, Porter Cable®, Low RPM Dry Cut Saws |

Safety

Always wear proper PPE to include (but not limited to) safety glasses, hearing protection, respirator, and hand protection. Keep all guards in place on your machine.