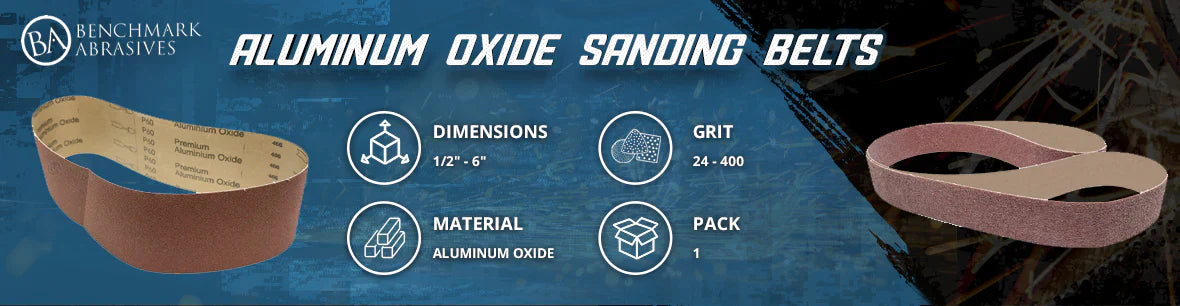

Benchmark Abrasives Aluminum Oxide (AO) Sanding Belts

If you’re in the business of sanding and finishing, you understand the importance of reliable, high-quality sanding belts. Aluminum oxide sanding belts are a top choice for professionals and hobbyists alike, offering durability and efficient material removal for both metal and wood applications.

Aluminum Oxide (AO) Sanding Belts, What are they?

Aluminum oxide sanding belts are abrasive tools used in sanding applications. Comprising a flexible backing material coated with aluminum oxide abrasive grains, these belts are designed to fit various belt sanders. Aluminum oxide is highly valued for its hardness, strength, and ability to achieve a smooth finish on both soft and hard materials.

Why Choose Aluminum Oxide Sanding Belts?

- VERSATILITY – Ideal for both metal and wood sanding.

- DURABILITY – Long-lasting abrasive grains that maintains its cutting edge.

- EFFICIENCY – Provides quick material removal while minimizing heat buildup.

- COST-EFFECTIVENESS – Aluminum oxide is the most economical grain option. This lower cost option is a go to for hobbyists and weekend warriors with more time than budget.

What should you use your AO sanding belts on?

- Metal Sanding Applications – Perfect for smoothing edges, removing rust, and preparing surfaces for welding or painting.

- Wood Sanding Applications – Excellent for shaping, smoothing, and finishing wood surfaces without clogging the abrasive grain.

Choosing the Right Aluminum Oxide Sanding Belt for Your Job:

- Grit Size: The grit size you choose depends on your specific needs. Coarse grits (40-60) are best for heavy material removal, medium grits (80-120) for general sanding, and fine grits (150-240) for finishing.

- Backing Material: Choose a strong backing material like cotton, polyester, or a blend to ensure durability and flexibility. Not sure what you need, give us a call and we can help walk you through your options.

- Belt Size: Ensure the belt size matches your sander. Your sander should come with an operators guide. We suggest checking the guide to ensure you are purchasing the correct belt for your machine. Too tight or too loose belts can affect performance and safety.

Choosing the Right Grit:

AO Sanding Belts come in various grit options, ranging from coarse to fine grits. Selecting the right grit for your sanding application is crucial for achieving the desired finish. Coarse grits are ideal for rapid material removal, while fine grits are best suited for finishing and polishing tasks.

- Coarse Grits: 40-60

- Medium/Coarse Grits: 80-100

- Medium Grits: 120-150

- Fine Grits: 180-220

- Very Fine Grits/Finishing: 240 and up

What Size Belt Do I Need?

By far the fastest way to determine your sanding belt size is to take an existing belt and measure it. Sanding belts are measured width by length so a 2 x 48 belt would be 2” wide and 48” long (sanding belt length is the circumference of the belt). There are two methods for determining belt length using an existing belt:

Cut it in half and measure the total length

-or-

Press the belt flat and measure from end to end. Take that number and double it for overall length

We don’t suggest cutting a new belt as that would render it useless. Instead save that method for older worn-out belts that have little or no useful life left in them.

If your still having an issue determining your belt size, feel free to reach out to our team with your machine info and we will do our best to find the correct sizing for you.

Benchmark Abrasives stocks belt widths 3/8” to 6” and 13” to 79” in total length. You can use the handy filters on the left side of the screen to easily find the belt that fits your needs.

How to Use Aluminum Oxide Sanding Belts Effectively

- Proper Installation: Always ensure that the belt is installed correctly, with the arrow on the belt lining up with the direction of rotation of the sander. Running your belt in the wrong direction can snap the belt joint rendering your belt useless.

- Correct Pressure: Apply consistent, light pressure to avoid overheating the material and the belt.

- Regular Maintenance: Clean the belt regularly to extend its life and maintain its sanding efficiency. Use one of our abrasive belt cleaning sticks or compressed air to remove dust and debris.

Maintaining Aluminum Oxide Sanding Belts

- Storage: Store in a cool, dry place to prevent moisture damage and warping.

- Cleaning: Periodically clean belts to remove resin build-up and maintain optimal performance. Extend the life of your belt with our belt butter and clean up with our abrasive belt cleaning sticks.

- Inspection: Check for wear and tear regularly. Replace belts when abrasive grains wear down to avoid compromising the finish quality. If your belt has a snag or a tear in it, it’s time to throw new belt on your machine. Damaged belts can damage workpieces by leaving unintended scratch patterns behind.

My Sanding Belt Is Clogged And Won’t Sand Anymore, Is It Trash?

- Not necessarily. Sanding Belts, like all other coated abrasives, are subject to loading up. This is more prevalent when sanding softer materials like woods or non-ferrous metals like aluminum. You can extend the useful life of your abrasive belt by using one or both of our sanding accessories; belt butter and our cleaning stick

- Belt Butter – a life extending grease that helps to prevent coated abrasives from loading up. Apply some of the belt butter before you get your grind on and say good riddance to the material load up.

- Cleaning Stick – an industrial rubber eraser that removes the material loaded up on any sanding disc or sanding belt. Bring the cleaning stick to the belt while it is running and it will knock out the material, leaving you with a renewed belt and added life.