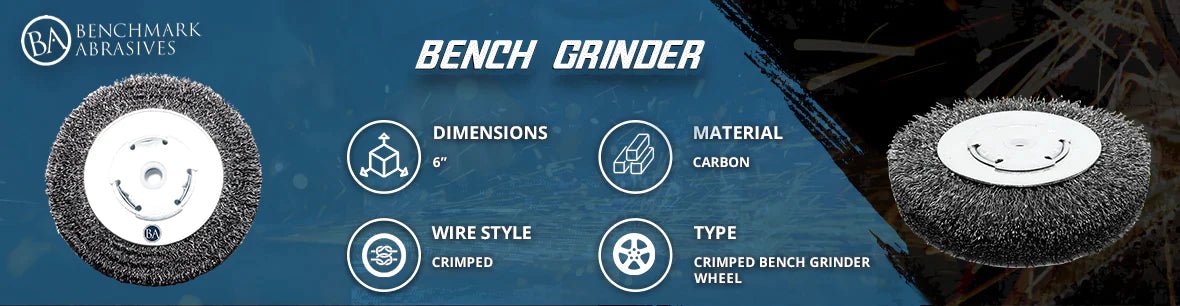

Bench Grinder Wire Wheel

Bench grinder wire wheels are wire brushes that provide a flexible brushing action and cost-effective performance in general-purpose cleaning and deburring applications. These bench grinder wire wheels are optimal abrasive tools for cleaning rust and removing paint. They are also used to clean surfaces and to create a better conductive area for attaching electrical connections. They can be used on straight grinders and stationary machines such as bench grinders, pedestal grinders, and buffing lathes. The bench grinder wire wheel is designed for cleaning and deburring rust and dirt, edge blending, roughening for adhesion, and weld prep.

Carbon steel brushes can be used on ferrous metal (Cast Iron, Steel, Titanium, Nickel, Wrought Iron), concrete, masonry, and building materials.

Common Uses of a Bench Grinder Wire Wheel

A big part of the value of bench grinders is their versatility. Some of their many uses include:

- Rust and Paint Removal: Strip rust, paint, and corrosion from metal surfaces, prepping them for refinishing or reuse.

- Deburring: Remove sharp edges or leftover burrs after cutting or machining to improve part safety and function.

- Surface Preparation: Clean surfaces before painting, welding, or coating to improve adhesion and reduce failure risks.

- Polishing and Finishing: Lightly polish metal parts to enhance their look and feel or create a more uniform surface.

Why Choose Carbon Steel Wire?

- Durability: Carbon steel wires stand up to heavy-duty use, tackling rust, paint, and debris without wearing down quickly.

- Cost-Effective: Offers a budget-friendly option for users needing reliable performance across general-purpose applications.

- Versatility: Well-suited for use on ferrous metals and tough materials like masonry and concrete.

What to Consider Before You Buy a Bench Grinder Wire Wheel

Wire Material

- Carbon Steel: Great for cast iron and steel surfaces.

- Stainless Steel: Works best on stainless and aluminum—prevents contamination and rust.

- Brass: Softer touch for light-duty work or non-sparking environments.

Wire Diameter

- Fine Wire: Gentler on surfaces, helps avoid scratching or gouging.

- Coarse Wire: More aggressive—gets through stubborn rust or paint faster.

Wheel Size and Thickness

Choose a size that matches your grinder. Larger wheels speed up broad surface work, while thinner options fit into tight areas.

Arbor Compatibility

Double-check arbor hole size for a snug, secure fit with your bench grinder’s spindle.

RPM Rating

Always match the wire wheel’s RPM rating to your grinder’s operating speed.

Wire Style

- Crimped Wire: Designed for light to medium-duty tasks. The individual crimped bristles are flexible, making them suitable for cleaning delicate or irregular surfaces without removing too much material.

- Knotted Wire: Built for heavy-duty cleaning. The tightly twisted wires offer more aggressive action and are better for cutting through thick rust, weld slag, and scale.

Tips for Getting the Most Out of Your Wire Wheel

For optimal performance of your wire wheel, follow these basic usage tips:

- Safety: Wear PPE such as safety glasses, gloves, hearing protection, and a dust mask. Keep all guards in place on your machine.

- Mount It Right: A securely installed wheel runs straighter and lasts longer.

- Use Consistent Pressure: Let the wire do the work. Pushing too hard could wear it out unnecessarily.

- Keep It Moving: Glide your material across the wheel to avoid hot spots or uneven wear.

- Stay Below Centerline: Present the workpiece below the wheel’s horizontal midpoint to maintain control and reduce kickback risk.

Troubleshooting and Maintenance

Proper use and maintenance go a long way, but occasional issues can still come up. Here’s how to troubleshoot some common ones:

Too Much Vibration?

Check for a loose or unbalanced wheel. Remove, clean, and reinstall carefully. A balancing kit may help if the issue persists.

Losing Cleaning Power?

Grit and debris between wires can reduce performance. Clean your wheel regularly to restore efficiency.

Breaking Wires?

This often means too much pressure or the wrong wheel for your material.

After-Use Care

- Clean off debris and grime after each use.

- Dress the wheel when needed to maintain shape and performance.

- Store in a dry place to avoid rust and deterioration.

Bench grinders from Benchmark Abrasives are built for consistent, high-performance results on the toughest jobs. If for any reason you are not happy with your product, we make returns easy. Just send us an email, use the chat button, or give us a call. We'll set you up with an RGA and return shipping info without any stress or hassle. FREE SHIPPING for orders over $100.