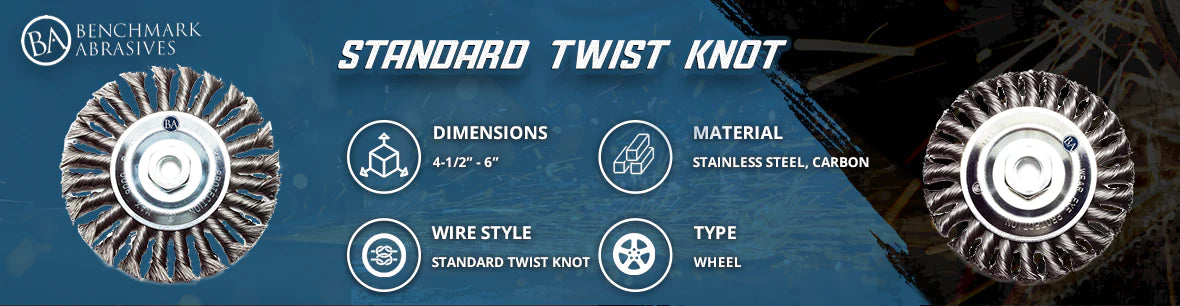

Standard Twist Knot Wire Wheels for Heavy-Duty Cleaning

Standard Twist Knot Wire Wheels from Benchmark Abrasives are made for serious surface prep. Built with tightly twisted, high-tensile steel wire, these wheels deliver the stiffness and power you need to blast through rust, slag, scale, and weld spatter. If you’re in fabrication, shipbuilding, or maintenance work, these are the brushes you reach for when a clean surface isn’t optional—it’s essential.

The twist-knot design delivers more aggression and longer life than crimped wire styles, making them ideal for demanding jobs. You’ll find a variety of options in this collection, including cup brushes and stringer bead wheels that are commonly used for weld cleanup, bevel prep, and pipeline maintenance.

Whether you’re running a bench grinder, angle grinder, or hand-held tool, we’ve got a wheel that fits.

Why Choose Standard Twist Knot Wire Wheels?

Our standard twist-knot wire wheels are designed for powerful surface preparation and cleaning. Whether you need to remove rust, scale, weld spatter, or clean pipes, these wire wheels provide exceptional performance. The tightly twisted, high-tensile steel wire provides both stiffness and durability, ensuring a longer-lasting tool for industrial tasks.

Key Benefits:

-

Ideal for use with angle grinders, bench grinders, and other power tools

-

Perfect for deburring, cleaning, and polishing

-

Provides superior performance in heavy-duty applications

-

Available in various sizes and wire materials, including stainless steel

Types of Wire Wheels Available

Carbon Steel Wire Wheels

Our carbon steel wire wheels are built for heavy-duty surface preparation and cleaning tasks. They deliver maximum aggression for removing tough materials like rust, paint, and scale from metal surfaces. Available in multiple sizes from 4" to 6" diameters.

Stainless Steel Wire Wheels

For applications requiring corrosion resistance or when working with stainless materials, our stainless steel wire wheels are the ideal choice. They offer excellent durability, won't contaminate stainless surfaces, and provide high performance in both wet and dry environments.

Applications Across Industries

Our standard twist knot wire wheels are trusted by professionals across industries:

-

Fabrication and Welding: Remove slag, weld spatter, and clean metal surfaces

-

Automotive Repair: Clean and prepare metal parts for finishing

-

HVAC Installation: Prepare and clean ducts, pipes, and fittings

-

Metalworking: Smooth and deburr edges for precision results

-

Construction and Maintenance: Clean large surfaces, remove corrosion, and polish

What to Consider When Buying a Wire Wheel

Before you choose a wire wheel, consider the following specs and application needs:

- Wheel Diameter: Common sizes include 3", 4", 6", and 7". Larger wheels cover more surface area and remove material faster.

-

Wire Size (Gauge):

- Heavier gauges (0.020”–0.025”) provide more aggression and durability.

- Finer wires (0.014”) allow more control and reduce surface damage on lighter-duty tasks.

-

Arbor Hole or Shank Type:

- Arbor hole diameters range from 5/8"-11 to 7/8".

- Shaft-mounted wheels often come with 1/4" or 1/2" shanks—check compatibility with your tool.

- Wire Material: High-carbon steel is standard for general-purpose metal prep. Stainless steel options are available for non-corrosive or food-grade applications.

- Tool Compatibility: Ensure your tool's RPM rating matches the wheel's max RPM. Never exceed the wheel’s rated speed.

Tips for Use

Wire wheels can wear quickly or cause injury if used incorrectly. These tips help you get the most out of your tool—safely and effectively:

-

Use light, even pressure. Let the twisted wires do the work. Pushing too hard can reduce wheel life and damage your part.

-

Keep the tool moving. Holding the wheel in one spot can gouge your surface or cause overheating.

-

Always orient the brush correctly. Work so the wires spin away from sharp edges or corners to prevent kickback.

-

Use the right RPM. Never exceed the max RPM marked on the wheel. Slower speeds offer more control and reduce risk.

- Start with a test pass. Especially on unfamiliar materials, test the wheel on a scrap piece or edge before going all in.

Why Buy From Us?

We offer high-quality, long-lasting wire wheels that can handle tough jobs in demanding environments. When you purchase from us, you receive premium quality products that meet industry standards at competitive pricing for top-tier wire brushes. We ensure fast shipping for timely project completion and provide expert customer support to assist with product selection and technical advice. Our commitment to excellence means you can trust our wire wheels to deliver reliable performance when you need it most.

Fast Shipping and Easy Returns

We offer fast shipping on all orders and free shipping on purchases over $100. If your order doesn’t work out, returns are quick and hassle-free. Just reach out by email, chat, or phone, and we’ll help you get set up with an RGA and return instructions.

Need a different wire brush for your setup? Browse our full selection of Wire Wheels to find the right fit for your next job.