Ultimate Guide to Benchmark Abrasives Gas Powered Saw Blades for Metalworking and Construction

When it comes to achieving precision and efficiency in metalworking and construction, the choice of tools plays a critical role. Among the most essential tools are bonded abrasive gas-powered saw blades. These powerful blades are engineered to handle the toughest materials, providing unmatched cutting performance.

Why Choose Benchmark Abrasives Gas Powered Saw Blades?

- SUPERIOR CUTTING EFFICIENCY: Bonded abrasive saw blades are designed to cut through metals and other hard materials with high efficiency. The bond in the blades holds the abrasive grains together, ensuring a sharp and durable cutting edge.

- VERSATILITY: These blades are suitable for a wide range of materials, including stainless steel, carbon steel, cast iron, and various composites. This makes them ideal for diverse applications in metalworking and construction.

- DURABILITY: The bonded abrasive construction provides long-lasting performance, reducing the frequency of blade replacements and ensuring continuous operation without frequent downtimes.

- PRECISION: They offer precise cuts with minimal burrs, ensuring clean and accurate finishes that meet the highest quality standards. This precision reduces the need for secondary finishing, saving both time and money.

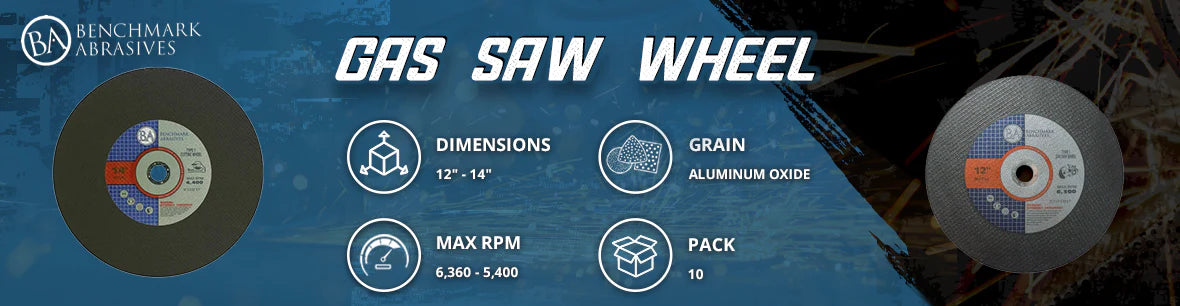

Gas Saw Wheels Available at Benchmark Abrasives

Gas Saw Wheels feature heat-treated aluminum oxide grains, which are triple external reinforced with high tensile strength fiberglass that allows for safe, fast cuts without vibrations & burrs even during extreme applications and high speeds. These Gas Saw blades can be used to cut steel, structural steel, rebar, iron pipe, bar stock, angle iron, metal tubing, etc.

Ideal for metal applications such as stainless steel, sheet metal, cast iron, and a variety of other materials.

- Sizes: 12” and 14”

- Thicknesses: 1/8” (5/64”)

- Available Formulas: Steel/Stainless

Tool Compatibility: Gas Powered Saws ONLY

Safety Tips for Using Gas Saw Blades

- Protective Gear: Always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and hearing protection. Check out our full line of PPE to keep you safe while using our tools.

- Proper Storage: Store blades in a dry place to prevent moisture damage, which can compromise their integrity.

- Regular Inspection: Before each use, inspect the blade for cracks, chips, or other signs of damage. Cracked and damaged wheels are unsafe for use.

- Secure Mounting: Ensure the blade is securely mounted to the saw and that the machine's guard is in place and functional.

- Use the correct Machine with the correct RPM: This is the most important safety tip on the page…ONLY USE GAS SAW WHEELS ON GAS POWERED SAWS. Using blades without the correct RPM rating will cause the wheel to break apart violently. Alternately, the slower chop saws will not have enough speed to efficiently cut.

Machine Brands that are compatible with Benchmark Gas Saw Wheels

- Black & Decker®

- Bosch®

- Ridgid®

- Ryobi®

- Skil®

- Porter Cable®

- Cobalt®

- Dewalt®

- Milwaukee®

- Makita®

- Craftsman®

- Norton®

- Metabo®

- And more…

Safety

Always wear proper PPE to include (but not limited to) safety glasses, hearing protection, respirator, and hand protection. Keep all guards in place on your machine.

FAQS

What the heck are bonded abrasive gas saw wheels?

They’re tough-as-nails cutting wheels made for high-speed gas-powered saws. Think of them as the workhorse of the cutting world. They’re built to handle the heat, high RPMs, and abuse we dish out on the job.

Can these cut through anything, or do they have limits?

They’re not magic, but they sure come close. These wheels are great for cutting steel, rebar, angle iron, bar stock, iron pipe, and metal tubing. Need to slice through stainless steel or cast iron? No problem. Just don’t try using them on wood or plastic—you’ll be disappointed (and probably mad).

How do I pick the right size wheel?

Check your saw specs and grab a wheel that matches. Common sizes are 12-inch or 14-inch, usually about 1/8-inch thick. Don’t be “that guy” forcing the wrong size wheel on your saw—it’s dangerous and won’t end well.

Can I store these wheels anywhere?

Store them somewhere dry and cool—no extreme temps, no soaking them in oil. Treat them like your favorite wrench set: with care. And don’t forget to rotate your stock so you’re not using a wheel from the last decade.

Do Gas Saw Wheels expire?

Yep, they’ve got a shelf life, usually around two years. After that, they can lose their mojo. If you find an old one lying around, inspect it like your life depends on it—because it kind of does.

What’s the secret to making these last longer?

Three words: Don’t. Abuse. Them. Let the wheel do the work—don’t shove it into the material like you’re in a hurry to go home. Avoid side pressure, clamp down your material, and keep your saw in good shape. It’ll save you money and headaches.

What should I do if the wheel starts vibrating or feels “off”?

Stop. Right. There. That’s usually a sign something’s wrong—like it’s mounted crooked or it’s damaged. Fix it before you keep going, or you’ll regret it.

How do I know if the wheel’s damaged?

Look for cracks, chips, or missing pieces. Tap it lightly and listen—if it doesn’t make a solid “ring” sound, it’s toast. Do NOT use a sketchy wheel. Unless you like explosions.