Deburring Wheels Built to Handle the Tough Jobs

A deburring wheel is a type of coated abrasive, built for smoothing rough edges left behind after cutting, drilling, or welding. Tough and reliable, these wheels remove burrs without grinding away too much material, giving you a clean finish that’s ready for the next step.

They’re a go-to in machine shops, fabrication plants, and assembly lines. Whether you're prepping metal for paint or cleaning up after a weld, deburring wheels keep the process smooth and the results consistent.

What They’re Built For

Deburring wheels tackle tough surface prep tasks. They knock down rough edges, clean joints, and blend corners. The result: smoother surfaces and safer parts that meet spec.

Workers rely on them to:

- Remove burrs from milled or cut metal

- Smooth weld seams without grinding too deep

- Condition surfaces before coating

- Blend machined edges for uniformity

Who Uses Them

These wheels show up across industries. Machinists, welders, fabricators, and even aerospace techs count on them to keep parts clean and to code. You’ll find deburring wheels in places where precision and efficiency matter.

Available Options

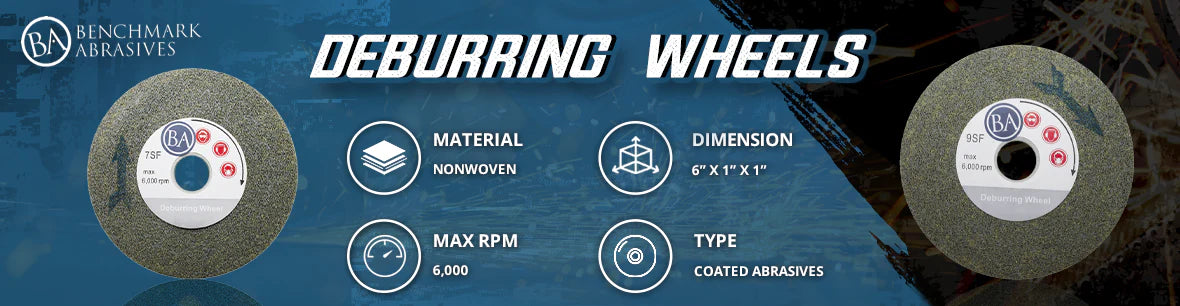

- Sizes: 6” x 1” x 1”

- Grain Options: Silicon Carbide

Grit Types

- Light Grit Wheels: Ideal for delicate finishing tasks and refining surfaces.

- Medium Grit Wheels: Great for general-purpose deburring and material removal.

- Coarse Grit Wheels: Excellent for aggressive burr removal and smoothing rough edges.

The Right Fit for Your Tools

Deburring wheels are compatible with bench grinders, pedestal grinders, die grinders, and other rotary tools. Be sure the arbor size and wheel specs match your tool. Most wheels bolt on quickly and stay in place under load.

Built to Perform Deburring Wheels

A deburring wheel is only as good as its construction. Resin bonds keep the structure solid under load, while the non-woven abrasive surface removes material evenly without gouging. Different grades and densities let you match the wheel to the part—whether you're after a light finish or serious burr removal. It’s about choosing the right tool to stay efficient and consistent.

These deburring wheels are perfect for precision finishing tasks such as removing weld spatter, deburring sharp edges, and preparing surfaces for processes like painting or welding. Their durable construction and efficient design ensure optimal performance in demanding environments, making them a reliable choice for professional metalworkers, fabricators, and craftsmen.

For additional surface preparation solutions, explore our full range of coated abrasives to find the right tools for your needs.

FAQs

What makes a deburring wheel different from a grinding wheel?

Deburring wheels are less aggressive than grinding wheels. They’re designed for surface finishing, not heavy stock removal.

Can I use a deburring wheel on plastic parts?

Yes. Use a softer, fine-grade wheel to avoid melting or gouging the plastic.

How long will one wheel last?

Lifespan depends on the material and pressure used, but a good wheel holds up for several hours of steady use.

Do I need protective gear to use these wheels?

Always. Eye protection, gloves, and hearing protection are standard for safe operation.