Benchmark Abrasives Tungsten Carbide Tipped (TCT) Saw Blades for Cutting Wood

In the world of construction and wood working, the choice of saw blade can significantly impact the quality of your work. Tungsten carbide tipped (TCT) saw blades are a popular option known for their durability, precision, and efficiency.

Why Choose Tungsten Carbide Tipped Saw Blades?

Tungsten carbide is one of the hardest and most durable materials available, making it an excellent choice for cutting tools. When used in saw blades, tungsten carbide tips offer several benefits:

- LONGEVITY – TCT blades retain their sharpness longer than steel blades, reducing the need for frequent replacements.

- PRECISION – These blades provide cleaner, more accurate cuts due to their sharpness and minimal vibration.

- VERSATILITY – Suitable for a wide range of materials including hardwood, softwood, plywood, and even some non-ferrous metals.

Types of TCT Saw Blades for Different Applications

Benchmark Abrasives carries a wide range of wood cutting blades to meet just about every cutting application. Below is an explanation of our different blade options:

FINE FINISHING

Usage: Ideal for final passes on visible wood surfaces.

Features:

- High tooth count (60 to 100 teeth).

- Produces a smooth, splinter-free finish.

- Slower cutting speed due to higher precision.

FRAMING AND FINISHING

Usage: Suitable for both the structural and aesthetic elements of a project.

Features:

- Moderate tooth count (40 to 60 teeth).

- Balances speed and smoothness.

- Used for cutting framing lumber and trim.

GENERAL PURPOSE

Usage: Can handle a variety of cuts across different materials.

Features:

- Tooth count varies (30 to 50 teeth).

- Versatile, balanced performance.

- Suitable for both rip cuts and crosscuts.

GENERAL PURPOSE AND FRAMING

Usage: Designed for rough construction cuts and framing tasks.

Features:

- Tooth count (24 to 40 teeth).

- Rougher cuts but faster cutting speed.

- Built for toughness and durability.

GENERAL PURPOSE AND TRIMMING

Usage: Perfect for both rough cuts and detailed trimming.

Features:

- Tooth count (40 to 60 teeth).

- Capable of smooth edges and accurate measurements.

- Versatile for various stages of a project.

QUICK CUT AND TRIMMING

Usage: Optimal for faster, less precise cuts.

Features:

- Lower tooth count (20 to 30 teeth).

- Emphasis on speed over smoothness.

- Suitable for quick cuts on framing lumber.

RIPPING

Usage: Specialized for ripping along the grain.

Features:

- Low tooth count (20 to 25 teeth).

- Wider gullets for fast waste removal.

- Ideal for making long, straight cuts.

ULTRA FINE FINISHING

Usage: For the highest quality, smoothest cuts on finished surfaces.

Features:

- Very high tooth count (80 to 120 teeth).

- Extremely smooth finish, minimal tear-out.

- Best for high-visibility areas requiring superior aesthetics.

TCT Blades Available at Benchmark Abrasives

Benchmark carries three categories of TCT blades, designed to match your material and machine.

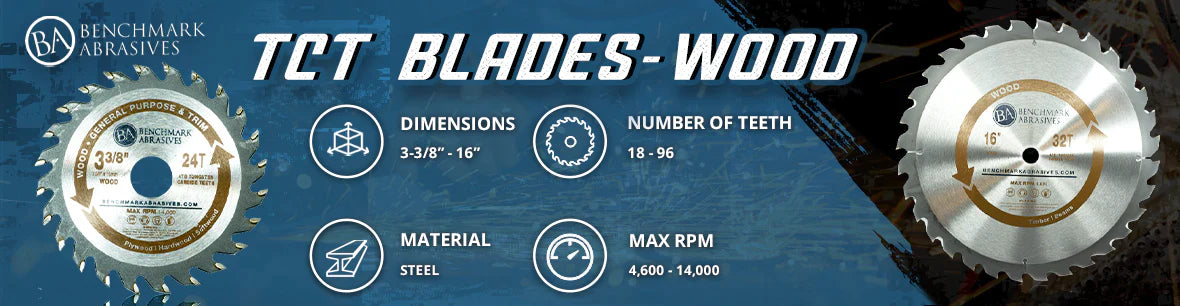

1. TCT Blades for WOOD - Tungsten Carbide Tipped (TCT) Circular Saw Blade allows you to cut faster and smoother, which makes this blade an excellent option for hardwoods, softwoods, and plywood. Tungsten carbide construction adds durability, securing a lot of life out of this saw blade. These wood cutting blades ensure fast and accurate cutting with impressive results.

- Sizes: 3-3/8” to 16”

- Number of Teeth: 18T, 24T, 32T, 36T, 40T, 60T, 64T, 72T, 80T, 96T

- Cutting Applications: Fine Finishing, Framing & Finishing, General Purpose, Ripping, General Purpose & Framing, General Purpose & Trimming, Ultra Fine Finishes

- Available kerfs: 0.053” to 0.134”

- Tool Compatibility: Beam Saws, Circular Saws, Miter Saws, Radial Arm Saws, Table Saws

2. TCT Blades for METAL (check out the TCT Blades for Metal/Steel page for more info)

3. TCT Blades for ALUMINUM (check out the TCT Blades for Aluminum page for more info)

Choosing the Right TCT Saw Blade for Your Job

When selecting a TCT saw blade, consider the following factors:

- Type of Material: Ensure the blade is suitable for the material you are cutting.

- Blade Diameter: Match the blade size with your saw's specifications.

- Tooth Configuration: Different tooth designs (flat top, alternate top bevel, combination, etc.) affect cutting performance.

- Cut Quality: Higher tooth counts generally offer smoother cuts but may reduce cutting speed.

Maintenance and Care

Proper maintenance can extend the life of your TCT saw blades:

- Cleaning. Regularly remove resin and debris build-up.

- Sharpening. Have your blades professionally sharpened to maintain performance.

- Storage. Store blades in a dry, safe place to prevent damage.

- Routine Inspection. Check for signs of wear or damage before each use to ensure safety and efficiency. If your blade is warped it will not provide straight cuts.

Machine Brands that are compatible with Benchmark TCT Blades for Wood

- Bosch®

- DeWalt®

- Makita®

- Milwaukee®

- Panasonic®

- Skil®

- Hitachi®

- Ryobi®

- Evolution®

- Metal Devil®

- Porter-Cable®

- Jepson®

- Other Low Horsepower Saws

Machine Selection by Blade Size

Check out this handy chart for suggested machine brands best suited for each size of blade.

|

Blade Diameter |

Max RPM |

Compatible Machine Brands |

|

5-3/8" |

4200 |

Panasonic®, DeWalt®, Bosch®, Makita®, Milwuakee®, Skil®, 5-1/2" Ryobi® |

|

6-1/2" |

4600 |

DeWalt®, Milwuakee®, corded and cordless |

|

7-1/4" |

5800 |

Corded and Corsdless Circualr Saws - ALL brands |

|

8" |

5800 |

Milwaukee® 8-1/4" Wormdrive Saws |

|

8-1/4" |

5800 |

Evolution® Fury3®, corded and cordless |

|

9" |

3200 |

Hitachi®, Jancy®, Evolution®, Metal Devil® |

|

10" |

5200 |

Evolution®, Miter Saws |

|

12" |

2000 |

Jepson®, Makita®, Ridge®, Ryobi® |

|

14" |

1800 |

DeWalt®, Jepson®, Hitachi®, Porter Cable®, Low RPM Dry Cut Saws |

Safety

Always wear proper PPE to include (but not limited to) safety glasses, hearing protection, respirator, and hand protection. Keep all guards in place on your machine.