Benchmark Abrasives Flap Wheels for Metalworking and Welding

When it comes to metalworking and welding, achieving a smooth, refined finish is paramount. Enter flap wheels—versatile, efficient abrasive tools used for grinding, sanding, and finishing metal surfaces. Whether you're a professional welder, an industrial metalworker, or a DIY enthusiast, understanding the benefits and applications of both mounted and unmounted flap wheels can significantly enhance your work quality and productivity.

What Are Flap Wheels?

Flap wheels are coated abrasive tools made up of multiple overlapping pieces of sandpaper-like material, called flaps, which are arranged radially around a center hub. These wheels are specifically designed to provide a consistent finish as they wear evenly, exposing fresh abrasive with each use.

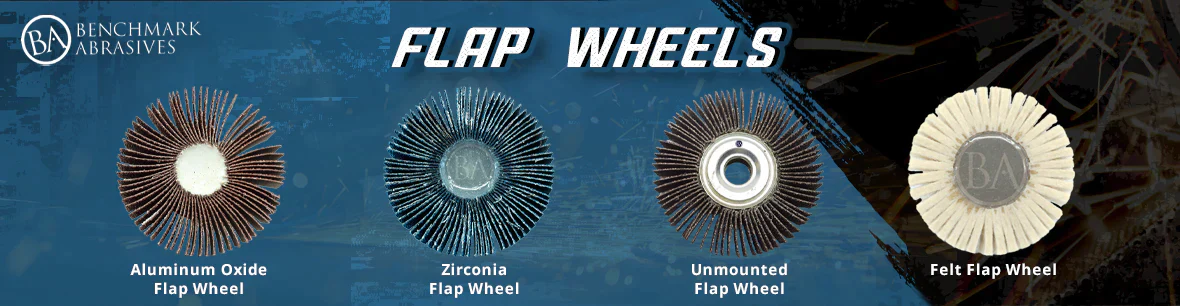

Types of Flap Wheels

Flap wheels are available in two main types:

- Mounted Flap Wheels: These have a spindle or shank, allowing them to be used with drills, die grinders, and other handheld power tools. Usually found in sizes as small as 1/2” or as large as 3”

- Unmounted Flap Wheels: These are designed to be used with bench grinders and stationary pedestal grinding machines, typically having a central hole to attach to these larger devices. Usually found in sizes 4” and larger.

What Are the Benefits of Using Abrasive Flap Wheels

VERSATILITY – Flap wheels can be used on a variety of materials, including:

- Stainless steel

- Aluminum

- Carbon steel

- Non-ferrous metals

EFFICIENCY – Flap wheels provide a consistent cutting rate and finish, reducing the need for multiple tool changes. They’re ideal for applications such as:

- Deburring

- Surface blending

- Rust removal

- Edge grinding

DURABILITY – Flap wheels are known for their long lifespan. The overlapping flaps wear down gradually, continually exposing fresh abrasive material, which results in prolonged and consistent performance.

Flap Wheel Applications in Metalworking and Welding

- Surface Preparation: Before welding, it’s crucial to have a clean, smooth surface. Flap wheels excel at removing contaminants, old paint, and rust, preparing the metal for a high-quality weld.

- Weld Blending: Post-weld, flap wheels can be used to blend the weld bead into the surrounding metal. This is particularly useful for achieving a smooth finish before painting or coating.

- Edge Grinding: The flaps' flexibility allows for precise edge grinding, making sharp edges smoother and safer without damaging the surrounding material.

- Precision in tight spaces: One of the standout features of Abrasive Flap Wheels is their ability to access and work within tight and hard-to-reach spaces.

Choosing the Right Flap Wheel

-

Grit Size: Flap wheels come in various grit sizes, ranging from coarse to fine.

- Coarse (36-60 Grit): For removing heavy material and rough sanding.

- Medium (80-120 Grit): Perfect for intermediate sanding and blending.

- Fine (150-3000 Grit): For finishing and smoothing tasks.

-

Material: Flap wheels are made from various abrasive materials, such as:

- Aluminum Oxide: Suitable for general-purpose metalworking.

- Zirconia Alumina: Offers a longer lifespan and is ideal for high-pressure grinding.

- Ceramic Alumina: Best for heavy-duty applications and tough materials.

Best Practices for Using Flap Wheels

- Safety First: Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Consistent Motion: Keep the flap wheel moving to prevent gouging the material. Let the flap wheel do the work!

- Appropriate Speed: Operate at the recommended speed for the specific wheel and material to ensure optimal performance and safety.

Flap Wheels Available at Benchmark Abrasives

Flap wheels are designed to grind and finish hard-to-access areas such as the inside of pipes, inside radius or tubes. They are made of multiple abrasive sheets attached to a core for fabricating, deburring, cleaning, polishing, and finishing jobs in metalworking and woodworking applications. Flap wheels are one of the most useful tools to have in metal fabrication. Coated abrasives flap wheels are used for most applications from grinding to polishing. Flap wheels are commonly used on ferrous alloy, high tensile materials, and finish complex shapes and tight contours on a workpiece. They can attach to grinders, drills, impact wrenches, or handheld rotary tools.

- Sizes Available: 3/4" x 3/4", 1” x 1”, 1-1/2” x 1”, 2” x 1”, 2-1/2” x 1”, 3” x 1”, 3” x 2”, 4”, and 6” (variety of thicknesses available in the 6” bench grinder flap wheels)

- Bench Grinder Flap Wheel Thicknesses: 1/2", 1”, 1-1/2” and 2”

- Inner Diameter Options: 1/4” shaft mounted, 5/8” and 1”

- Materials: Aluminum Oxide (AO), Zirconia, Ceramic, Nonwoven Surface Conditioning, Interleaf and Felt for buffing.

- Grits Available: 40, 60, 80, 120, 180, 240, 320, Coarse, Medium and Fine

Tool Compatibility: Rotary Drills and Die Grinders, Pneumatic Air Tools, Bench Grinders and Pedestal Grinders

Machine Brands that are compatible with Benchmark Flap Wheels

- Black & Decker®

- Bosch®

- Ridgid®

- Ryobi®

- Porter Cable®

- Mirka®

- Festool®

- Cobalt®

- Dewalt®

- Milwaukee®

- Makita®

- Craftsman®

- Norton®

For more information, tips, and product recommendations, don’t hesitate to contact our expert team. Happy sanding!

Safety

Always wear proper PPE to include (but not limited to) safety glasses, hearing protection, respirator, and hand protection. Keep all guards in place on your machine.