Type 27 Bonded Abrasive Grinding Wheels for Metalworking and Welding

Are you a professional welder or metalworker seeking the best tools to enhance your craft? Look no further. Benchmark Abrasives Type 27 bonded abrasive grinding wheels are tailored to meet your specific needs with their high performance and efficient material removal rate.

What Are Type 27 Bonded Abrasive Grinding Wheels?

Type 27 bonded abrasive grinding wheels (also known as Depressed Center Wheels) are specially designed for grinding metal. The unique shape of these wheels allows for optimal angle grinding, making them ideal for various metalworking and welding applications.

Grinding Wheels vs Cutting Wheels

While grinding wheels and cutting wheels may look similar, they serve distinct purposes in metalworking. Understanding the difference helps you choose the right tool for your application.

Grinding Wheels are thicker (typically 1/8" to 1/4") and designed for surface work—removing material, smoothing welds, shaping edges, and preparing surfaces. Their added thickness provides stability for applying pressure at various angles against the workpiece.

Cutting Wheels are much thinner (usually 1/16" or less) and engineered specifically for slicing through metal. Their thin profile allows for fast, clean cuts with minimal material loss, but they should never be used for grinding or side pressure applications.

Key Differences at a Glance:

|

Feature |

Grinding Wheels |

Cutting Wheels |

|---|---|---|

|

Thickness |

1/8" – 1/4" |

1/16" or less |

|

Primary Use |

Material removal, blending, shaping |

Cutting through metal |

|

Contact Area |

Face and edge of wheel |

Edge only |

|

Pressure Application |

Can handle side pressure |

No side pressure—breakage risk |

Using the wrong wheel for a task can compromise both your results and your safety. Always select a grinding wheel when you need to remove material or smooth surfaces, and reserve cutting wheels for making cuts.

Why Choose Type 27 Bonded Abrasive Grinding Wheels?

- VERSATILITY – From precision grinding to heavy material removal, Type 27 wheels cater to a variety of metal types and welding materials. Whether working with stainless steel, carbon steel, or other alloys, these grinding wheels can handle just about any job.

- EFFICIENCY – The shape and aggressive grit formula of Type 27 wheels ensure fast stock removal with minimal effort. This efficiency saves time, decreasing project turnaround time and increasing overall productivity.

- DURABILITY – Engineered to withstand rigorous use, Type 27 wheels offer enhanced durability, making them a cost-effective choice. The robust construction ensures a long lifespan, reducing the frequency of replacements.

- SAFETY – Designed with user safety in mind, these wheels feature multiple layers of reinforced construction that minimize the risk of breakage. When used correctly, Type 27 wheels provide a safer working environment.

What Are Some Ideal Applications of Type 27 Grinding Wheels?

Type 27 grinding wheels are versatile and can be applied in numerous scenarios across metalworking and welding:

- Grinding and Blending Welds: Perfect for smoothing weld beads and blending them with the base material.

- Surface Preparation: Ideal for rust and paint removal, ensuring a clean surface before welding or painting. For finer finishing, follow up with sanding discs, PSA discs, or hook-and-loop discs to achieve a smooth, polished surface.

- Material Removal: Efficiently grind to shape different metal components.

- Beveling and Edge Preparation: Create precise bevels or prep edges for welding.

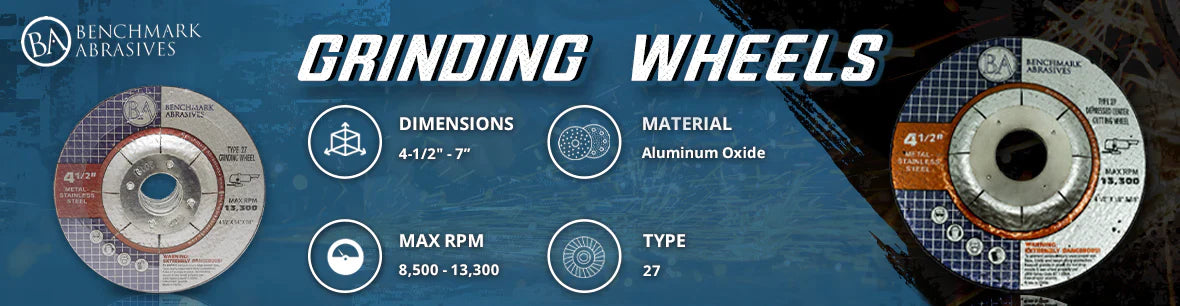

Grinding Wheels Available at Benchmark Abrasives

Depressed Center Grinding Wheels are suitable for general grinding of stainless steel, carbon steel, and other ferrous metals. Grinding Wheels are made to meet both ANSI and EN Standards. These wheels allow for a recessed locking nut to permit various grinding and cutting applications. Designed with the operator in mind, these grinding wheels are formulated for fast stock removal balanced with long service life.

They are manufactured with multiple layers of fiberglass, Bakelite resin, and European Aluminum Oxide grain. These wheels have set the benchmark for cost-efficient grinding.

- Sizes: 4-1/2”, 5”, 6”, 7”

- Thicknesses: 1/4” and 1/8”

- Available Formulas: Steel/Stainless and Aluminum Cut

Tool Compatibility: Angle Grinder

How to Choose the Right Type 27 Grinding Wheel For Your Job

Selecting the correct Type 27 wheel depends on your specific needs. Consider the following factors:

- Abrasive Material: Match the abrasive type (aluminum oxide, silicon carbide, zirconia alumina) to your material.

- Grit Size: Choose a grit size based on the desired finish—coarser grits for fast material removal and finer grits for smooth finishes.

- Bond Strength: Ensure the bond strength aligns with your application’s demand for durability and performance.

Grinding Wheel Maintenance and Usage Tips

To maximize the life and performance of your Type 27 grinding wheels, follow these tips:

- Proper Storage. Store wheels in a dry environment to prevent damage from moisture. Storing your grinding wheels in humid and moist environments can reduce the overall life of the product.

- Correct Mounting. Ensure the wheel is properly mounted on the grinder to avoid imbalance and potential accidents. If the grinder starts violently shaking when you turn it on, TURN THE GRINDER OFF and inspect the mounting.

- Appropriate PPE. Always wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection. Benchmark has a full range of PPE for proper grinding protection.

- Regular Inspection. Frequently inspect wheels for cracks or wear and replace them as needed. A cracked wheel can break apart into chunks.

Brands Compatible with Benchmark Grinding Wheels

- Black & Decker®

- Bosch®

- Ryobi®

- Skil®

- Porter Cable®

- Cobalt®

- Dewalt®

- Milwaukee®

- Makita®

- Craftsman®

- Norton®

- Metabo®

- And more…

Safety

Abrasive grinding wheels operate at high speeds and demand respect. Taking shortcuts with safety can lead to severe injuries. Whether you're working on a lengthy project or a quick task, always follow these precautions.

- Wear appropriate personal protective equipment: safety glasses, hearing protection, respirator, and heavy-duty gloves

- Examine wheels carefully before each use—look for cracks, chips, or any visible damage and discard compromised wheels immediately

- Verify that your wheel size is compatible with your angle grinder

- Confirm the grinder's RPM does not exceed the wheel's rated maximum speed

- Allow the tool to reach full speed before beginning work

- Wait for the wheel to stop spinning completely before putting the grinder down

- Maintain a firm two-handed grip on the tool at all times during operation

- Keep the factory guard installed and in proper position—never operate without it

- Avoid loose-fitting clothes, ties, dangling jewelry, or anything that could catch in the spinning wheel

For quality protective gear, Benchmark Abrasives carries a complete line of PPE designed for grinding applications.