Benchmark Abrasives 1” x 42” Sanding Belts

Benchmark Abrasives carries a wide range of sanding belts from large to small.

Machine Brands that are compatible with Benchmark 1” x 42” Sanding Belts

There are many different machines that can handle 1” x 42” sanding belts. We’ve narrowed down a few options, however there are many more on the market:

- Kalamazoo® 1SM Belt Sander: A versatile and robust machine well-suited for 1" x 42" sanding belts. Known for its reliability and precision work.

- Grizzly® G1015 Knife Belt Sander/Buffer: This model is specifically designed for knife making but is versatile enough for general sanding tasks. It perfectly accommodates 1" x 42" belts.

- JET® J-4002 Bench Belt and Disc Sander: A popular bench-mounted sander that fits 1" x 42" sanding belts. Ideal for both woodworking and metalworking projects.

- Shop Fox® W1843 Knife Belt Sander/Buffer: Designed for knife makers but also efficient for other tasks requiring precision sanding, it uses 1" x 42" belts.

- Powertec® BD4600 Belt Disc Sander: This combination belt and disc sander can handle 1" x 42" sanding belts and provides flexibility for a variety of sanding projects.

- Rikon® 50-120 Belt & Disc Sander: This versatile sander accommodates 1" x 42" belts and offers a combined belt and disc sanding solution for various applications.

When choosing a machine, always confirm with the manufacturer or product specifications that it supports the exact belt size you need. Also, consider that some machines might require additional accessories or modifications to perfectly fit less common belt sizes.

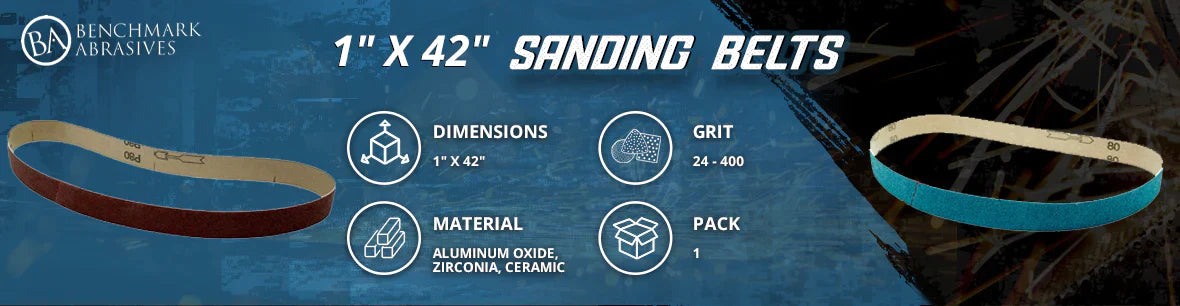

1” x 42” Sanding Belts Available at Benchmark Abrasives

- Width: 1”

- Length: 42”

- Grits: 24, 36, 40, 50, 60, 80, 100, 120, 150, 180, 220, 240, 320, 400

- Grain Options: Aluminum Oxide, Zirconia and Ceramic

- Backing: X-weight polycotton cloth

- Joint: Butt joint

- Coat: Closed Coat

Tool Compatibility: Belt & Disc Sander Combination machines, Benchstand Grinders, Portable Belt Sanders, Backstand Belt Grinders, 1” x 42” belt sanders and Knife Belt Sanders

What’s the Difference Between AO, Zirconia and Ceramic?

Benchmark stocks three different grain options in most of our stocked sizes; Aluminum Oxide, Zirconia and Ceramic.

Aluminum Oxide (AO) – Aluminum Oxide is the most commonly used grain at an economical price point. Great for use on ferrous metals, composite materials, wood, plastics, and other metals. It features good abrasion resistance, anti-static and anti-clogging.

Zirconia – Zirconia grains have a self-sharpening property and stand up to higher heat and pressure than Aluminum Oxide (A/O), thus making Zirconia the go-to option, providing excellent stock removal that gives you more bang for your buck. They are designed for use on ferrous metals, composite materials, wood, plastics, and other metals.

Ceramic – Ceramic grains micro fracture to allow a continuous supply of the sharpest cutting edges. It's also self-cooling which makes it great for stainless steel and high alloy materials. The lower grits hog up metal for lightning-fast stock removal and the longest cutting life available. They are the best option for mild and carbon steel, stainless, cobalt, chrome, Inconel, and titanium applications.

What Grit Should I Be Using?

Grit size determines the aggressiveness of the sanding belt. The smaller the number the more aggressive the grain is, the larger the number the less aggressive it is. Grits 24-40 are generally considered aggressive material removers, 60-80 grits are for medium material removal and grits 120+ are all in the light material removal/finishing category.

If you are unfamiliar with the difference in each grits aggressiveness, we recommend grabbing a scrap piece of metal and a few different grits to start off with. Start with the smaller more aggressive grit and work your way up the grit scale to get a good feel for how they each perform. Once you’ve done that you’ll be ready for any project you pick.

My Sanding Belt Is Clogged And Won’t Sand Anymore, Is It Trash?

Not necessarily. Sanding Belts, like all other coated abrasives, are subject to loading up. This is more prevalent when sanding softer materials like woods or non-ferrous metals like aluminum. You can extend the useful life of your abrasive belt by using one or both of our sanding accessories; belt butter and our cleaning stick

Belt Butter – a life extending grease that helps to prevent coated abrasives from loading up. Apply some of the belt butter before you get your grind on and say good riddance to the material load up.

Cleaning Stick – an industrial rubber eraser that removes the material loaded up on any sanding disc or sanding belt. Bring the cleaning stick to the belt while it is running and it will knock out the material, leaving you with a renewed belt and added life.

I Can’t Find What I Need!

Don’t stress…we’ve got you covered. Benchmark Abrasives can custom make just about any belt you need, from small belts to wide belts, AO grains to Surface Conditioning, we can do it all. If you can’t find the size or grit you need, head back to the home page and click the Custom Belt Link, fill out your specs and we’ll get you a quote. Its that easy!