Powerful and Precise 2” x 72” Sanding Belts

Benchmark Abrasives carries a comprehensive range of abrasive belts from small specialty sizes to wide industrial options, with our 2" x 72" sanding belts representing some of the most versatile and popular choices for serious craftsmen and professionals across metalworking, woodworking, knife making, and countless other applications.

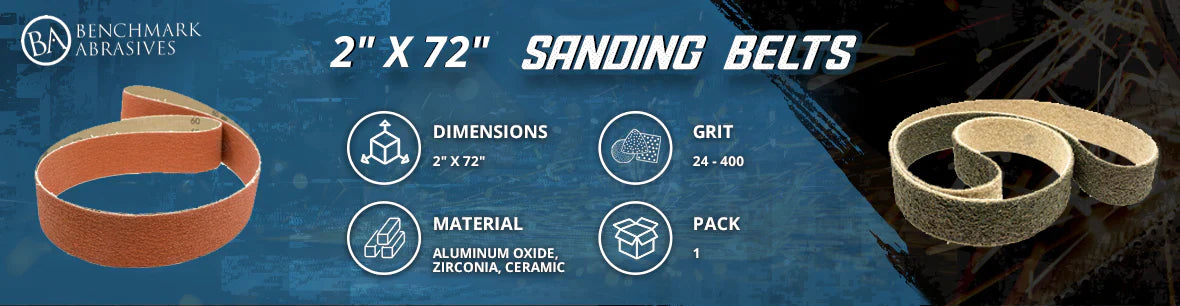

2” x 72” Sanding Belts Available at Benchmark Abrasives

- Width: 2 inch x length: 72"

- Grits: 24, 36, 40, 50, 60, 80, 100, 120, 150, 180, 220, 240, 320, 400, plus Coarse, Medium and Fine options

- Grain Options: Aluminum Oxide, Zirconia, Premium Ceramic and Surface Conditioning

- Backing: X-weight polycotton cloth and Y-weight polyester options with flexible backing

- Joint: Butt joint construction

- Coat: Closed coat for maximum cutting efficiency

Machine and Tool Compatibility for Benchmark 2" x 72" Sanding Belts

Benchmark's 2" x 72" sanding belts are designed to work with a wide range of equipment, from specific branded machines to various tool categories.

Here are some popular machine models that are specifically designed for 2" x 72" belts:

-

Kalamazoo® 3SM 2" x 72" Belt Sander: Known for its durability and efficiency, this sander is specifically designed for 2" x 72" belts, making it ideal for metalworking, woodworking, and knife making.

-

Grizzly® G1015 Knife Belt Sander/Buffer: Originally designed for knife making, this machine handles 2" x 72" belts and is versatile enough for both detailed and general sanding tasks.

-

Jet® J-4103 2"x72" Square Wheel Belt Grinder: This robust sander is designed for 2" x 72" belts and features a square wheel, offering versatility for various grinding and sanding tasks.

-

Esteem Grinders® Esteem Belt Grinder: A professional-grade machine designed for 2" x 72" belts, commonly used by knife makers and metalworkers for its precision and reliability.

-

Multitool USA® Belt Grinder Attachment (MT482): This attachment converts your existing bench grinder into a versatile sanding machine that can handle 2" x 72" belts.

-

KMG Industrial® Belt Grinder: A durable and powerful machine designed for professional use, accommodating 2" x 72" belts, popular among knife makers and metalworkers.

-

VASHTO® 2" x 72" Belt Grinder: Known for its high quality, this customizable grinder is suitable for 2" x 72" belts and is popular in the knife-making community.

-

TR Maker® 2" x 72" Belt Grinder/Sander: Another popular model in the knife-making community, designed to handle 2" x 72" belts with precision and efficiency.

-

Burr King® 960-272 Knifemaker Belt Grinder: A specialized grinder for knife makers, this machine handles 2" x 72" belts and is known for its quality and reliability.

- Beaumont Metal Works® KMG Belt Grinder: Highly customizable and designed for professional use, it supports 2" x 72" belts and is a favorite among serious metalworkers and knife makers.

General Tool Categories

These belts are also compatible with various equipment types including Belt & Disc Sander Combination machines, Benchstand Grinders, Portable Belt Sanders, Backstand Belt Grinders, and Knife Belt Sanders.

When choosing a machine, always confirm with the manufacturer or product specifications that it supports the exact belt size you need. Also, consider that some machines might require additional accessories or modifications to perfectly fit less common belt sizes.

Understanding Different Abrasive Grain Types

Benchmark offers four grain options, each designed for specific applications and performance needs.

Aluminum Oxide is the most economical and widely used option. It works well on ferrous metals, composites, wood, plastics, and other metals while offering good abrasion resistance with anti-static and anti-clogging properties.

For more demanding applications, Zirconia grains feature self-sharpening technology and handle higher heat and pressure than Aluminum Oxide. This makes them ideal for heavy stock removal applications, delivering superior value through extended belt life on the same materials.

When maximum performance is required, Ceramic grains micro-fracture to continuously expose sharp cutting edges while remaining self-cooling. They excel on stainless steel and high-alloy materials, providing the fastest stock removal and longest cutting life. Ceramic works best on mild and carbon steel, stainless, cobalt, chrome, Inconel, and titanium.

For finishing work, Surface Conditioning belts take a different approach entirely. These non-woven belts are perfect for finishing, blending, color removal, and light deburring. Their waterproof construction allows use in both wet and dry applications.

What Grit Should I Be Using?

Grit size determines how aggressively your belt removes material from different types of workpieces. Lower numbers indicate more aggressive cutting action, while higher grits provide smoother finishing results. Grits 24-40 are considered aggressive material removers perfect for heavy stock removal tasks, while 60-80 grits handle medium material removal applications. Higher grits of 120 and above fall into the light material removal and finishing category, with fine grit options providing exceptional surface quality.

If you're unfamiliar with different grit performance characteristics, we recommend testing with scrap material and several different grits. Start with lower, more aggressive grits and work your way up the grit scale to understand how each performs on your specific workpieces. This hands-on approach will prepare you for any project you tackle.

My Sanding Belt Is Clogged And Won’t Sand Anymore, Is It Trash?

Not necessarily—there's often life left in that belt yet. Sanding belts naturally accumulate material buildup during use, especially when working with softer materials like wood or non-ferrous metals such as aluminum. You can extend your belt's useful life with two simple accessories designed specifically for this problem.

Belt Butter takes a preventive approach by creating a barrier that prevents material from sticking to your abrasive surface. Simply apply this specialized grease to your fresh belt before starting work to dramatically reduce buildup throughout your sanding session.

For already-loaded belts, the Cleaning Stick offers an effective solution. While your belt is running, bring this industrial rubber eraser into contact with the abrasive surface to grab and pull away embedded particles, essentially renewing your belt and restoring its cutting ability.

If You Can't Find What You Need—

Don’t stress…we’ve got you covered. Benchmark Abrasives can custom make just about any belt you need, from small belts to wide belts, AO grains to Surface Conditioning, we can do it all. If you can’t find the size or grit you need, head back to the home page and click the Custom Belt Link, fill out your specs and we’ll get you a quote. It's that easy!