How to Choose Carbide Burr For metal?

Choosing the correct carbide burr for metal depends on four key factors: the material you're working with, the desired application, the burr's shape and size, and its cutting style.

Key Selection Factors

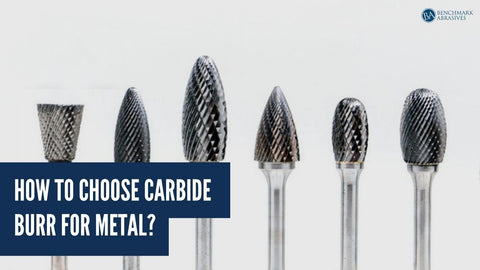

1. Burr Shape

The burr's shape determines its function and the type of cuts it can make.

- Cylindrical: Ideal for removing material from flat surfaces, contour finishing, and working on inside corners. Some have an end cut for flat surface grinding.

- Ball-shaped: Excellent for hollowing out material, creating concave cuts, deburring bores, and sculpting.

- Tree-shaped: Used for reaching tight, hard-to-access areas and creating tapered holes or contours. They come in both pointed and rounded end versions.

- Inverted Cone: Perfect for creating V-cuts, chamfering, and working on the backside of an edge.

- Flame-shaped: Great for detailed carving and sculpting.

2. Fluting Style (Burr Cut)

The grooves on the burr's surface, or "fluting," determine how quickly it removes material and the finish it leaves behind.

Single-Cut: This style has a single spiral flute and is designed for aggressive material removal. It creates long chips and is best used on harder materials like cast iron, stainless steel, and hardened steel.

Double-Cut: Also known as a cross-cut or diamond cut, this style has two sets of intersecting flutes. It creates smaller, shorter chips, provides a smoother finish, and is easier to control.

3. Shank and Burr Size

The shank size is the diameter of the stem that fits into your rotary tool (e.g., a die grinder). The most common sizes are 1/4" and 1/8". It is essential to choose a shank that fits your tool's collet tightly to prevent vibration and ensure a secure fit.

The burr size (diameter and length) should be chosen based on the dimensions of the cut you want to make. Smaller burrs are for intricate detail work, while larger burrs are for faster material removal on a larger scale.

Related Article: Carbide Burrs for Stainless, Aluminum, and Mild Steel

Types of Carbide Burrs

Carbide burrs are usually available in two cuts: single cut and double cut (diamond cut).

- Single-cut (one flute) carbide burrs have a right-handed (up-cut) spiral flute. These tend to be used with chrome steel, hardened steel, copper, cast iron, and ferrous metals, and can remove material quickly. They are used for heavy stock removal, deburring, and cleaning.

- Double-cut carbide burrs are used on ferrous and nonferrous metals, aluminum, soft steel, and non-metal materials such as plastics and wood. They need more cutting edges and can remove material faster. These are the most popular cuts and are used in most applications.

Safety Tips for Using Carbide Burr

In general, rotary burrs are relatively safe to work with. Because the grooves or flutes are fine, they often cut the skin when lightly touched. Yet, there are many things to keep in mind for safe operation and to increase the burr's lifetime. These include:

- Ensure the burr shank is tightly clamped within the collet, and it's inserted as far as possible to diminish overhang.

- Use light pressure, as excessive downward force can cause snagging and cause cut blemishes and chipping. Let the burr do the cutting.

- Secure your workpiece tightly and wear eye and face protection.

- Don't use an excessive spinning speed. Instead, start at a slower pace and gradually increase speed.