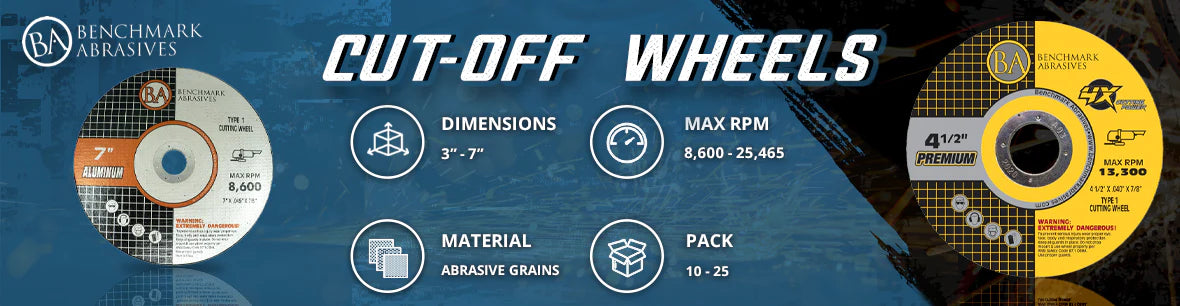

Cut-off Wheels

-

3" x 1/16" x 3/8" T1 Premium Thin Cut-off Wheel - 25 pack

Original price $0.00 - Original price $0.00Original price $0.00$16.05$16.05 - $16.05Current price $16.05| /5.0 / 5.0

28 Reviews

Product Specification Shipping Refund Product Specification 3" X 1/16" X 3/8" T1 PREMIUM THIN CUT-OFF WHEEL - 25 PACK 3" X 1/16" X 3/8" T1 Premi...

View full detailsOriginal price $0.00 - Original price $0.00Original price $0.00$16.05$16.05 - $16.05Current price $16.05| / -

4" x 1/16" x 3/8" T1 Premium Thin Cut-off Wheel - 25 pack

Original price $0.00 - Original price $0.00Original price $0.00$20.46$20.46 - $20.46Current price $20.46| /5.0 / 5.0

17 Reviews

Product Specification Shipping Refund Product Specification 4" X 1/16" X 3/8" T1 PREMIUM THIN CUT-OFF WHEEL - 25 PACK 4" X 1/16" X 3/8" T1 Premi...

View full detailsOriginal price $0.00 - Original price $0.00Original price $0.00$20.46$20.46 - $20.46Current price $20.46| /

Benchmark Abrasives Type 1 Cut-Off Wheels

Type 1 cut-off wheels are flat, bonded abrasive cutting wheels designed for thin, precise cuts in metal. Each bonded abrasive Type 1 cut-off wheel uses abrasive grains fused with durable binder materials and thermo-setting phenolic resins.

This construction delivers strength, longevity, and consistent cutting performance across a wide range of metals and shop environments.

Why Choose Type 1 Cut-Off Wheels?

-

Efficiency – Fast, smooth cutting with minimal effort

-

Clean Results – Reduced burrs and a thinner kerf for less material waste

-

Durability – Long-lasting bonded construction

-

Compatibility – Works with most angle grinders and cut-off tools

-

Precision – Reliable accuracy for tight-tolerance metal cutting

Best Applications for Type 1 Cut-Off Wheels

Benchmark Abrasives cut-off wheels are used in fabrication, such as steel pipe, sheet, bar, and profile cutting. They are used in construction for rebar, studs, and structural metals.

In automotive, use type 1 cut-off wheels for exhausts, bolts, and body panels. For maintenance, repair, and manufacturing, cut-off wheels are ideal for precision machining and metalworking.

Type 1 Cut-Off Wheels Offer Efficiency and Top Results

-

Precision Cutting – Straight, clean cuts with minimal waste

-

High Durability – Consistent, long-life performance

-

Versatility – For steel, stainless, aluminum, and non-ferrous metals

-

High-Speed Performance – Optimized for fast, productive cutting

-

Tested for Safety – Built to withstand demanding shop conditions

Choosing the Right Type 1 Cut-Off Wheel for Your Job

When choosing a Type 1 cut-off wheel, consider the following factors:

Abrasive Material: Choose a wheel with the appropriate abrasive grains (e.g., aluminum oxide for ferrous metals, silicon carbide for non-ferrous metals). Benchmark Abrasives offers three formulas: our signature Ba line, our 4X line with ceramic grains, and our Aluminum Cutting Formula for use on nonferrous materials.

Diameter and Thickness: Ensure the wheel size matches your equipment and cutting needs. Each machine comes with an operating manual. We suggest reading your owner's guide to ensure your cutting wheel matches your machine specifications.

RPM Rating: Confirm that the wheel’s maximum RPM rating is compatible with your tool to ensure safe operation. If the wheel fits on the machine but the RPMs don’t match, the wheel is not intended for that machine!

Best Practices for Using Bonded Abrasive Type 1 Cut-Off Wheels

Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

Ensure the wheel is securely mounted with the correct flanges and adheres to the manufacturer's instructions. If the wheel is not flush to the locking nut or flange, remove the wheel and affix it to the machine again.

Operate the wheel within the recommended speed limits to prevent breakage. Always FOLLOW ALL MAX RPM LABELS.

Avoid forcing the wheel; let the tool’s weight guide the cut and use steady, moderate pressure. Let the wheel do the work!

Frequently examine wheels for cracks, wear, or damage before use. Damaged wheels SHOULD NOT BE USED.

What Cut-Off Wheels Can Do

Cut-off Wheels provide premium performance and an increase in productivity. These discs are designed for use in angle grinders and are ideal for all types of metal/stainless steel materials as well as for cutting Fiberglass, Steel, Iron, Plastic, Stainless Steel, and other Ferrous Metals. They are internally reinforced with high tensile strength fiberglass.

Highly refined ingredients will not contaminate stainless steel. It offers fast, cool cutting that allows the operator to work with minimum pressure and a reduced heat-affected zone during cutting, minimizing burr creation.

Bottom line, these cut-off wheels offer LESS cutting resistance for fast work, LESS work piece waste, LESS vibration, LESS burrs and sparks, and LESS dust than the competition.

Sizes: 3”, 4”, 4-1/2”, 5”, 6”, 7”

Thicknesses: 0.040”, 0.045”, 1/16”, and 1/8”

Available Formulas: Steel/Stainless, 4X ceramic grain wheels, and Aluminum Cut

Tool Compatibility: Angle Grinder, Die Grinders, Air Powered Cut Off Tools, Electric Cut Off Tools, Skil Saws

Machine Brands That Are Compatible with Benchmark Sanding Discs

- Black & Decker®

- Bosch®

- Ridgid®

- Ryobi®

- Skil®

- Porter Cable®

- Cobalt®

- Dewalt®

- Milwaukee®

- Makita®

- Craftsman®

- Norton®

- Metabo®

- And more…

FAQS

How long does a cut-off wheel last?

Lifespan depends on material hardness, technique, and pressure. Steady, consistent cutting extends life.

Why is my wheel wearing down quickly?

Often caused by excessive pressure, incorrect RPM, or choosing the wrong wheel for the material.

What safety precautions should I take?

Wear eye and face protection, gloves, hearing protection, and keep machine guards in place.

What causes wheels to break or shatter?

Over-speeding, side pressure, incorrect mounting, or using damaged wheels.

How should I store cut-off wheels?

Keep them dry, cool, and away from moisture or extreme temperatures.

Is there a difference between premium and standard wheels?

Yes. Premium wheels cut faster, run cooler, and last longer, reducing downtime and overall cost.

Find the Right Type 1 Cut-Off Wheel for Your Job

Browse Benchmark Abrasives’ full lineup of high-performance type 1 cut-off wheels to get cleaner cuts, longer life, and better results on every project. Let our bonded abrasive technology deliver the precision your work demands.