Flap Discs

-

4-1/2" x 5/8"-11 T27 Zirconia High Density Trimmable Flap Disc - 1 Piece

Original price $0.00 - Original price $0.00Original price $0.00$4.19$4.19 - $4.19Current price $4.19| /4.9 / 5.0

17 Reviews

Product Specification Shipping Refund Product Specification 4-1/2" X 5/8"-11 T27 ZIRCONIA HIGH DENSITY FLAP DISC - 1 PIECE 4-1/2" x 5/8"-11 T27 ...

View full detailsOriginal price $0.00 - Original price $0.00Original price $0.00$4.19$4.19 - $4.19Current price $4.19| /

What Are Flap Discs?

Flap discs level up your grinding game by combining the material removal of a conventional grinding wheel with the control of a palm sander. The different abrasive grain sizes allow for a range of different finishes/scratch patterns and the cushion effect of the layered coated flaps allows for a lighter touch for feathered sanding or an aggressive metal hog. The pressure you apply dictates the aggressiveness of the disc.

What Makes a Flap Disc…a Flap Disc?

There are 3 main components that make up a flap disc; abrasive flaps, hard backing and glue

-

Coated Abrasive Flaps – Layers of overlapping coated abrasive cloth are applied to a hard backing (metal, plastic, or fiberglass) via a thermosetting phenolic resin (or glue). The abrasive flaps provide a cushion effect allowing the user to feather the grinding or bear down on the disc and really remove some material. This same coated abrasive technology is used in sanding discs, including PSA and Hook & Loop varieties, making flap discs a natural progression for users familiar with those products.

-

Hard Backing – Flap discs can be found with three different backing types (metal, plastic and fiberglass). The metal backed flap discs are not popular and are not commonly found in the US market. Fiberglass backed flap discs are the most common disc you will find. The fiberglass backing is coated in resins that harden under heat and pressure, leaving you with a rigid and lightweight backing to adhere the flaps to. The plastic backed flap discs have become more popular in the past few years with the design of a trimmable edge disc which can be cut back to expose more flap material.

- Glue – The stuff that holds it all together. A thermosetting resin (or glue) that liquifies under high heat, then cures to a hard rock like thickness. The glue holds the flaps firmly to the backing.

What Do T27 and T29 Mean?

T27 and T29 refer to the type, or shape of your flap disc. They are also commonly referred to as type 27 and type 29. T27 are flat and T29 are conical (or angled).

T27 – Type 27 flap discs are designed with a flat face. These discs are perfect for grinding on flat surfaces like fence posts or gates & risers. The flat face allows the user to bring the disc straight down on the work piece to ground down the protrusion. The ideal angle us of use for this type is 0 to 15 degrees for optimal flap usage.

T29 – Type 29 flap discs are designed with ergonomics in mind. The angled face allows for better, more ergonomic grinding and maximum flap usage when grinding a flat linear plane like grinding down bead weld. The ideal angle us of use for this type is 15 to 25 degrees for optimal flap usage.

…But What about the Curved Ones?

Curved – The latest addition to the flap disc shapes, “curved”, doesn’t come with a type or # call out. They are specially designed for grinding fillet welds and getting into other tighter radius. You may also hear them referred to as Fillet Weld Flap Discs

Which Flap Disc Grain Type Is Right for Your Project?

Not all flap discs are created equal—the abrasive grain you choose has a direct impact on cutting speed, disc longevity, and the quality of your finish. Understanding the differences between grain types helps you select the right disc for your material and application, saving you time and money in the long run.

Aluminum Oxide (AO)

Aluminum Oxide is the most commonly used grain at an economical price point. Great for use on ferrous metals, composite materials, wood, plastics, and other metals. It features good abrasion resistance, anti-static and anti-clogging.

Zirconia

Zirconia grains have a self-sharpening property and stand up to higher heat and pressure than Aluminum Oxide (A/O), thus making Zirconia the go-to option, providing excellent stock removal that gives you more bang for your buck. They are designed for use on ferrous metals, composite materials, wood, plastics, and other metals.

Ceramic

Ceramic grains micro fracture to allow a continuous supply of the sharpest cutting edges. It's also self-cooling which makes it great for stainless steel and high alloy materials. The lower grits hog up metal for lightning-fast stock removal and the longest cutting life available. They are the best option for mild and carbon steel, stainless steel, cobalt, chrome, Inconel, and titanium applications.

Surface Conditioning

Suitable for a multitude of applications, especially when finishing, blending, removing color from your work surface and light deburring applications. The fiber and resin are also waterproof so these belts can be used both in wet or dry applications.

Flap Discs for Aluminum & Non-Ferrous Metals

These flap discs excel on soft metals like aluminum. They don't gum up like a regular zirconia or aluminum flap disc. The stearate coating, which gives the flap disc its silver color, will liquefy under heat and provide a protective coat on the flaps that prevent loading/gumming up on soft metals.

Felt

While felt is technically not a grain, we do offer a special wool felt flap disc for ultimate polishing. Available individually or in one of our buffing kits.

Regular vs. Jumbo (aka High Density) Flap Discs

Regular density flap discs are our signature formula product, designed for both the professional grinding every day or the occasional user. For users looking for a longer life disc, we suggest the high density or Jumbo flap discs which contain 40-50% more flap content. More flaps = longer life.

What Grit Should I Be Using?

Available grits:

- AO – 40 grit through 120 grit

- Zirconia – 40 grit through 120 grit

- Ceramic – 36 grit through 120 grit

- Surface Conditioning – 120 through 320 grit

- Stearate Coated Discs for Non Ferrous Metals – 36 and 60

Grit size determines the aggressiveness of the flap disc. The smaller the number the more aggressive the grain is, the larger the number the less aggressive it is. Grits 24-40 are generally considered aggressive material removers; 60-80 grits are for medium material removal and grits 120+ are all in the light material removal/finishing category.

If you are unfamiliar with the difference in each grits aggressiveness, we recommend grabbing a scrap piece of metal and a few different grits to start off with. Start with the smaller more aggressive grit and work your way up the grit scale to get a good feel for how they each perform. Once you’ve done that you’ll be ready for any project you pick.

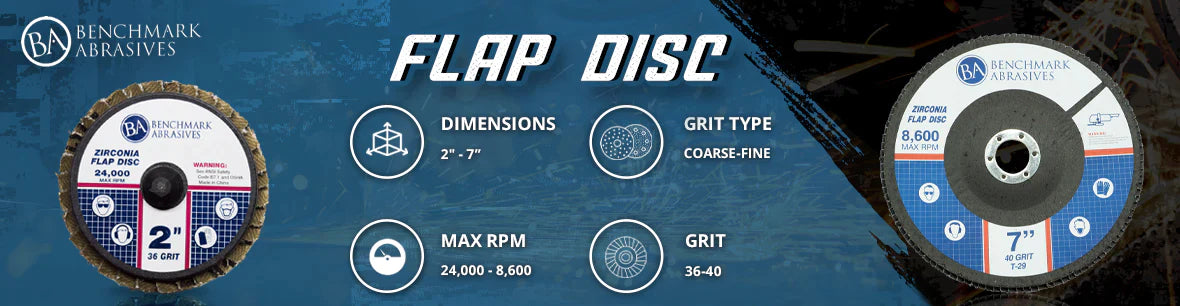

What Size Disc Should I be Using?

The flap disc size will be determined by the tool being used. Benchmark Abrasives carries 2” and 3” flap discs for die grinders/drills and 4”-7” flap discs for use on angle grinders. Make sure to match the size of the disc to your machines RPMs. Operating a 7” flap discs on a 4.5” machine is not safe and could result in injury.

Matching Materials to Your Disc Setup

Selecting the right flap disc isn't just about grit and size—it's about pairing the correct abrasive grain with the material you're working on. Here's a quick reference guide to help you dial in the perfect setup:

| Material |

Recommended Grain |

Notes |

|---|---|---|

|

Mild Steel / Carbon Steel |

Zirconia or Ceramic |

Zirconia offers excellent value; Ceramic provides faster cut and longer life |

|

Stainless Steel |

Ceramic |

Self-cooling properties prevent heat buildup and discoloration |

|

Aluminum & Non-Ferrous Metals |

Stearate Coated |

Prevents loading and gumming; essential for soft metals |

|

High Alloy Metals (Inconel, Titanium, Cobalt) |

Ceramic |

Handles high heat and maintains cutting efficiency |

|

Wood, Plastics, Composites |

Aluminum Oxide |

Economical choice for lighter-duty, non-metal applications |

|

Weld Blending & Finishing |

Surface Conditioning or Higher Grit Ceramic/Zirconia |

Start aggressive for removal, step up in grit for finishing |

What If I Don’t Have an Angle Grinder?

No grinder, no problem! Benchmark now has a full line of Quick-Change Flap Discs, available in both type 27 and curved (fillet weld) styles. These discs are designed with a hard plastic backing that has a roll lock (type R) or quick-change attachment. You can use these discs on die grinders, drills or any other tool designed to work with quick change discs.

Frequently Asked Questions

How should I store my flap discs?

Keep them in a dry, cool place away from direct sunlight and moisture. Humidity can degrade the resin bond and reduce cutting performance, while UV exposure can weaken the fiberglass backing over time. Ideally, store them flat or hanging vertically in their original packaging—treat them like your favorite six-pack, and they'll treat you right when you need them.

Any safety tips for using flap discs?

Always wear proper PPE including safety glasses or a full face shield, gloves, and hearing protection before operating your flap disc grinder. Inspect the disc for cracks, chips, or missing flaps before each use since a damaged disc can shatter at high RPMs. Make sure to stay within the recommended RPMs listed on the disc and always secure your workpiece to prevent dangerous kickback.

Why is my flap disc wearing out so quickly?

Excessive pressure is the most common culprit, so let the disc do the work rather than forcing it into the material. Using the wrong angle or selecting the wrong disc for your material can also cause rapid wear, as can running above the rated RPMs which generates excess heat and breaks down the resin bond. Evaluate your technique and disc selection since small adjustments often dramatically extend disc life.

How do I prevent clogging when working with softer metals?

Use discs specifically designed for non-ferrous metals, like our stearate-coated flap discs, which feature a coating that acts as a lubricant to prevent aluminum, copper, and brass from adhering to the abrasive. Apply lighter pressure and use intermittent grinding strokes rather than continuous contact to minimize heat buildup. Just like dancing, sometimes a lighter touch gets better results.

Is it safe to exceed the recommended RPM of a flap disc?

Absolutely not! The maximum RPM rating is determined by the structural integrity of the backing and bond under centrifugal force. Exceeding this rating can cause the disc to literally fly apart, sending fragments at dangerous speeds toward you and anyone nearby. Always match your flap disc for angle grinder applications to your tool's operating speed, and remember that smaller diameter discs generally have higher RPM ratings than larger ones.

What's the lifespan of a typical flap disc?

Lifespan varies widely based on the material being ground, grit selection, pressure and technique, and overall disc quality. With proper use and moderate pressure at the correct angle, a quality flap disc can last through multiple projects. High-density (Jumbo) discs offer 40-50% more flap material for users who need extended life from each disc.

Any tips for maximizing flap disc performance?

Use the right angle for your disc type—15-25 degrees for T29 discs and 0-15 degrees for T27—and let the disc do the work with moderate, consistent pressure. Periodically check for loading, especially on softer metals, since a clogged disc cuts poorly and generates excess heat. For finishing work, progress through grits sequentially rather than jumping from coarse to fine, or transition to finer-grit sanding discs for polished results.